|

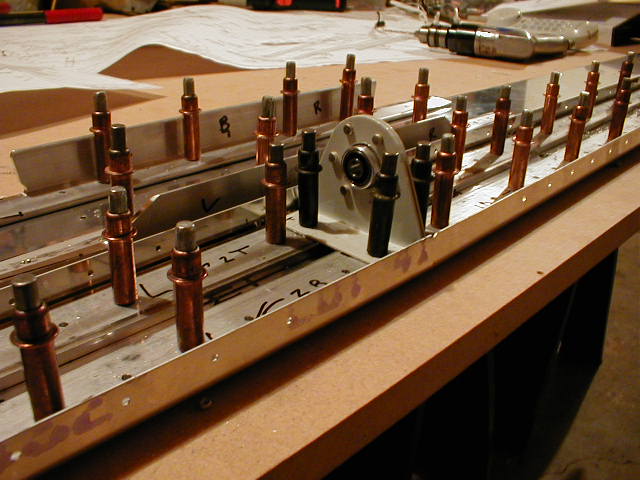

You will notice I have labeled the 603s and 609s so that you can place them back into their original positions

after you deburr. I used 1 right, 2 left, T top and B bottom. Worked for me.

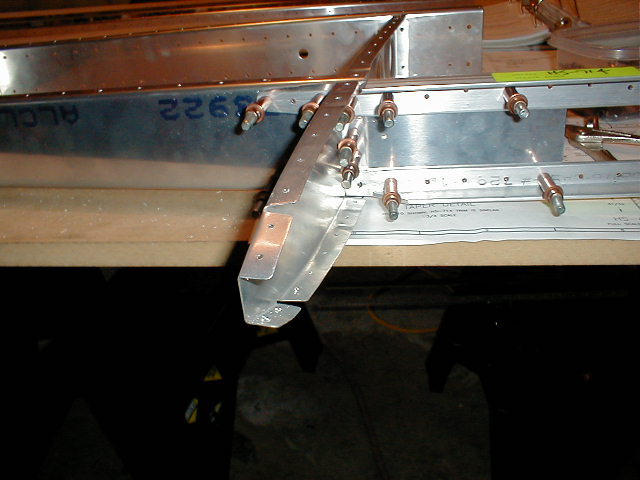

My way of making sure each bracket stays with it's partner. I marked the bottom flange of each bracket

to match a mark on the 603 or 609.

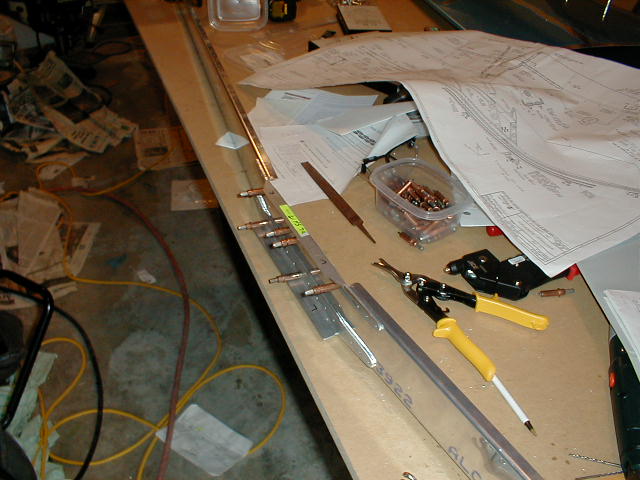

The 6 degree bends in the 710 and 714. At this point you final drill the holes outside the bend lines.

The holes are pre punched in the 710 and 714.

Now here is where the plans for the emps. sent out after the end of January 2002 differ from prior plans

(even prior 7 plans). At no point in the plans is "jig" or "plum" EVER mentioned. The only ribs not pre punched

are the inboard center (405) and inboard tip (406). With the other ribs pre punched the assembly can not be anything

other than plum. It does turn out straight. You drill the inboard 702 and the 404 and 405.

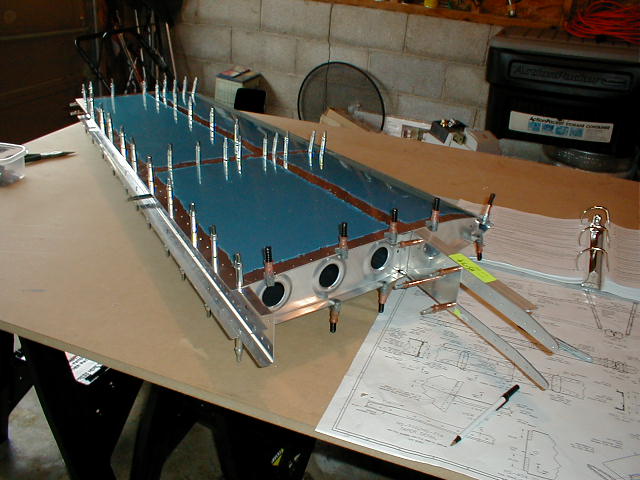

All holes are now final drilled.

The 601 skin now comes off and everything gets deburred and dimpled. You can see how jagged the holes

in the 404 are in this picture.

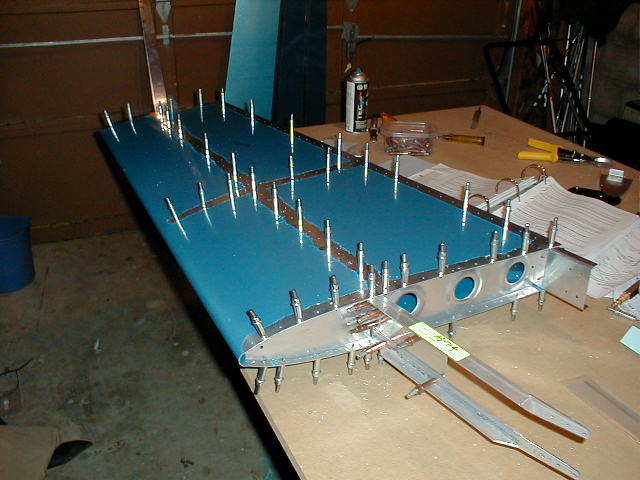

Everything deburred, dimpled and primed.

|